New Devices, New Challenges

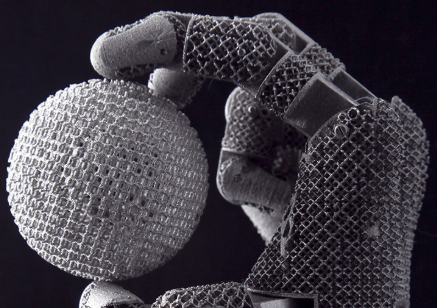

New Devices, New Challenges Biomedical gadgets frequently work at the cell level, implying that their segments' gaps, channels and different highlights might be tiny. The scope of gap measurements that JPSA machines is commonly between 1 micron and two or three hundred microns. Of course, gap breadths and relative component position resistances are additionally in the micron go. Despite the fact that the material thickness frequently can be close to 2 mm, opening perspective proportions (proportion of gap length to distance across) are regularly very high.

Laser Types

UV lasers expel material by a procedure called photograph removal. Progressive, high-redundancy laser beats expel modest, controlled measures of material. The limited quantity of removed material dissipates as a crest of plasma. Contingent upon the material being prepared, harmful gases might be created which would require a productive gas assortment and scrubber framework, for example, initiated charcoal canisters.

Gap Making Issues

Burrs are an issue with about each physical gap making process. The "burr" made during UV laser machining probably won't have the option to be felt with a fingernail, yet at the same time may influence a biomedical gadget's presentation. During laser machining, the material that is diverted into plasma and launched out from the surface rapidly cools over into a strong. If not gathered by a vacuum source basic to these laser frameworks, this material can rework around the edge of the component being machined. Recast material only a few microns tall could be critical for a 25-micron-distance across opening, for instance. A defensive covering can be applied to the objective material to confine this reevaluating impact. On the other hand, recast material can be expelled by auxiliary electro cleaning or compound treatment.

Precise Fixturing

Since part tainting is a major issue with numerous biomedical parts, installations might be covered with Teflon. Some medical clients venture to such an extreme as to determine a specific sort of glove administrators must wear while dealing with parts (without latex or sans powder gloves, for instance). For different clients, this is anything but a major issue, on the grounds that the parts will experience some sort of post-process cleaning to evacuate contaminants. It is critical to work intimately with a client's quality control office so the right taking care of strategies are followed.

Get Your Work done

Likewise with the reconciliation of any new innovation, there is an expectation to absorb information related with UV laser machining frameworks. In discovering increasingly about this machining procedure, it is ideal to invest energy conversing with shops at present utilizing lasers to discover what is associated with this other machining process so as to level the laser expectation to absorb information.